Workplace safety in industrial facilities depends heavily on visibility and clear hazard identification. Industrial environments often present challenging conditions with poor lighting, heavy machinery operation, and complex traffic patterns that require enhanced visibility solutions. Reflective tape serves as a critical safety component that significantly improves worker visibility and hazard awareness in these demanding environments. This retroreflective material transforms ordinary surfaces into highly visible markers that can prevent accidents and save lives across various industrial applications.

Understanding Reflective Tape Technology

Retroreflective Properties and Materials

Reflective tape operates on the principle of retroreflection, where light returns directly to its source regardless of the angle of incidence. This technology utilizes microscopic glass beads or prismatic structures embedded in the tape surface to achieve maximum light return. The glass bead technology creates millions of tiny spherical lenses that collect and redirect incoming light back toward the viewer. Modern prismatic reflective tape offers superior performance with engineered cube-corner retroreflectors that provide enhanced brightness and durability compared to traditional glass bead systems.

High-quality reflective tape incorporates weather-resistant adhesive backing and durable face materials designed to withstand industrial environments. The construction typically features multiple layers including a protective topcoat, retroreflective layer, adhesive system, and release liner. Premium grades utilize acrylic adhesives that maintain bonding strength across temperature extremes while resisting chemical exposure and UV degradation. These materials ensure long-term performance in demanding industrial applications where reliability cannot be compromised.

Performance Classifications and Standards

Industrial reflective tape must meet specific performance standards established by organizations such as ASTM International and the American National Standards Institute. These standards define minimum retroreflectivity levels, durability requirements, and testing protocols for different application categories. Type I reflective tape provides basic performance suitable for temporary applications, while Type III and Type IV grades offer superior retroreflectivity and extended service life required for permanent industrial installations.

The coefficient of retroreflection measures the tape's ability to return light to its source, with higher values indicating better visibility performance. Industrial applications typically require tape with retroreflectivity values exceeding 250 candelas per lux per square meter for optimal visibility under various lighting conditions. Understanding these performance metrics helps facility managers select appropriate reflective tape grades that meet their specific safety requirements and environmental challenges.

Industrial Applications and Safety Benefits

Equipment and Vehicle Marking

Mobile equipment and vehicles operating within industrial facilities require enhanced visibility marking to prevent collisions and improve operator awareness. Reflective tape applied to forklift trucks, maintenance vehicles, and material handling equipment creates a highly visible outline that remains effective in low-light conditions. Strategic placement on vehicle corners, edges, and rear panels maximizes visibility from multiple angles while helping operators judge distances and clearances more accurately.

Heavy machinery such as cranes, excavators, and industrial trucks benefit significantly from reflective tape applications that outline their operational boundaries and moving components. The tape helps nearby workers identify potential hazard zones while improving machine operator visibility of surrounding personnel. Consistent marking patterns across equipment fleets create visual recognition standards that enhance overall facility safety protocols and reduce accident risks associated with equipment interaction.

Pedestrian Walkways and Traffic Control

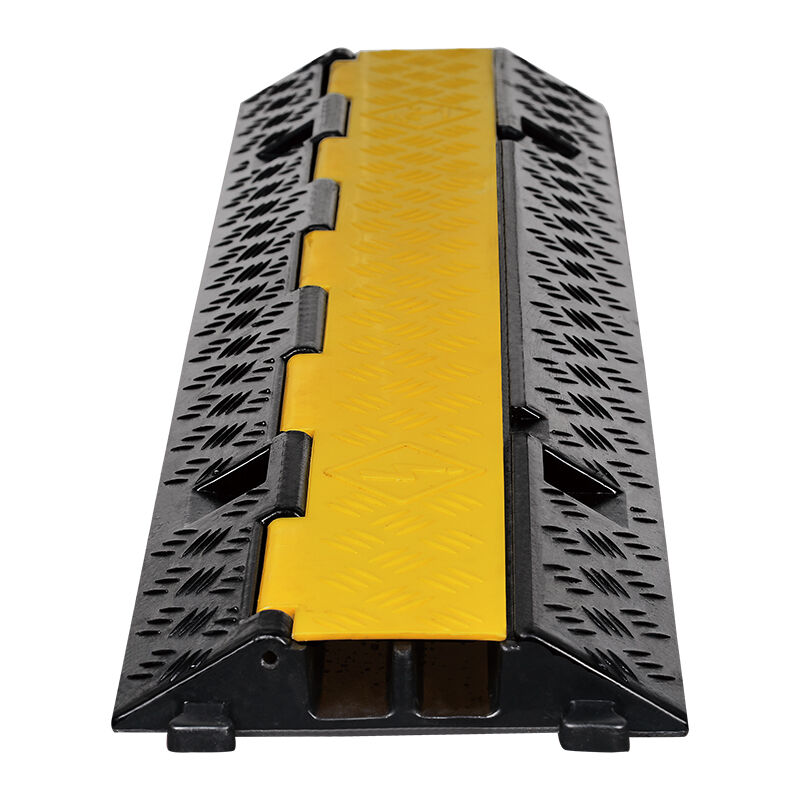

Designated pedestrian walkways in industrial facilities require clear delineation to separate foot traffic from vehicle operations and equipment zones. Reflective tape applied to walkway edges, handrails, and guidance posts creates visible pathways that remain effective during shift changes, emergency evacuations, and low-light maintenance activities. The enhanced visibility helps workers maintain proper routes while avoiding unauthorized access to hazardous areas.

Traffic control applications within facilities utilize reflective tape to enhance the visibility of temporary barriers, construction zones, and restricted access areas. The tape improves the effectiveness of safety cones, barricades, and warning signs by increasing their detection distance and recognition time. This enhanced visibility provides operators and pedestrians with additional reaction time to respond appropriately to changing traffic patterns and temporary hazards within the facility environment.

Installation and Maintenance Best Practices

Surface Preparation and Application Techniques

Proper surface preparation ensures optimal adhesive bonding and long-term performance of reflective tape installations. Industrial surfaces must be thoroughly cleaned to remove contaminants such as oil, grease, dirt, and oxidation that can compromise adhesive effectiveness. Solvent-based cleaners or alkaline degreasers may be required for heavily contaminated surfaces, followed by complete drying before tape application. Surface temperature during installation should remain within manufacturer specifications, typically between 50°F and 100°F for optimal adhesive activation.

Application technique significantly impacts tape performance and longevity in industrial environments. Proper installation requires applying consistent pressure during placement to achieve full adhesive contact with the substrate. Hand pressure or mechanical rollers should be used to eliminate air bubbles and ensure complete bonding across the entire tape surface. Edge sealing may be necessary in high-moisture environments or where chemical exposure is expected to prevent adhesive degradation and maintain reflective performance.

Inspection and Replacement Protocols

Regular inspection programs help maintain reflective tape effectiveness throughout its service life in industrial applications. Visual inspections should identify signs of wear, damage, or reduced retroreflectivity that could compromise safety performance. Measurement tools such as handheld retroreflectometers can provide quantitative assessments of tape performance compared to original specifications. Inspection frequencies should be established based on environmental exposure severity and criticality of the marked assets or areas.

Replacement criteria should be established before retroreflectivity falls below minimum safety thresholds or when physical damage compromises tape integrity. Proactive replacement programs prevent gradual performance degradation that might go unnoticed until visibility becomes critically compromised. Documentation of inspection results and replacement activities helps optimize maintenance schedules and identify areas where enhanced durability grades might provide better long-term value and safety performance.

Cost-Effectiveness and ROI Analysis

Accident Prevention and Insurance Benefits

Investment in reflective tape systems delivers measurable returns through accident prevention and reduced insurance costs in industrial facilities. Enhanced visibility provided by properly applied reflective tape significantly reduces collision rates between vehicles, equipment, and pedestrians. These accident reductions translate directly into lower workers compensation claims, reduced equipment damage costs, and decreased facility downtime associated with incident investigations and repairs.

Insurance providers often recognize proactive safety measures such as reflective tape installations through reduced premium rates or safety credit programs. Documented safety improvements and reduced loss histories can justify lower insurance costs that offset initial material and installation expenses. The relatively low cost of reflective tape compared to potential accident costs makes it one of the most cost-effective safety investments available to industrial facility managers.

Long-Term Performance Economics

High-performance reflective tape grades offer superior cost-effectiveness over their service life compared to economy alternatives that require frequent replacement. While premium grades have higher initial costs, their extended durability and maintained retroreflectivity provide lower total cost of ownership in demanding industrial environments. Service life advantages of 5-7 years for premium grades versus 2-3 years for standard grades result in reduced maintenance labor costs and fewer facility disruptions for replacement activities.

Energy cost savings represent an additional economic benefit of reflective tape installations that reduce artificial lighting requirements in marked areas. Enhanced visibility from retroreflective materials can allow reduced illumination levels while maintaining safety standards, resulting in measurable energy consumption reductions. These ongoing operational savings combine with safety benefits to provide compelling justification for quality reflective tape investments in industrial facility safety programs.

FAQ

How long does reflective tape typically last in industrial environments

The service life of reflective tape in industrial environments varies significantly based on environmental exposure and tape grade selection. Premium prismatic grades can provide 5-7 years of effective performance under normal industrial conditions, while standard glass bead types typically last 2-3 years. Factors such as chemical exposure, abrasion, temperature cycling, and UV radiation can reduce service life, making proper grade selection critical for cost-effective installations.

What is the difference between glass bead and prismatic reflective tape

Glass bead reflective tape utilizes microscopic spherical glass beads embedded in the surface to create retroreflection, offering good performance at lower cost points. Prismatic reflective tape uses engineered cube-corner retroreflectors that provide superior brightness, wider observation angles, and better durability. Prismatic types typically cost more initially but offer enhanced performance and longer service life that justify the investment in demanding industrial applications.

Can reflective tape be applied over painted surfaces

Reflective tape can be successfully applied over painted surfaces provided the paint is well-adhered, fully cured, and properly cleaned before installation. The paint must be compatible with tape adhesives and able to withstand the removal forces if tape replacement becomes necessary. Fresh paint should cure for at least 30 days before tape application, and surface preparation should include thorough cleaning to ensure optimal adhesive bonding to the painted substrate.

What surface preparation is required for optimal tape adhesion

Optimal reflective tape adhesion requires clean, dry surfaces free from contaminants that could interfere with adhesive bonding. Surface preparation should include degreasing with appropriate solvents, removal of loose paint or corrosion, and complete drying before tape application. Surface temperature during installation should be within manufacturer specifications, typically 50-100°F, and relative humidity should be below 85% for best results. Proper preparation is essential for achieving maximum tape performance and service life in industrial environments.