Modern logistics and warehousing operations face increasing pressure to maintain safe, efficient, and compliant facilities. Among the critical infrastructure elements that often go overlooked are driveway curb ramps, which serve as essential transitional zones between roadways and facility entrances. These specialized ramps address significant safety concerns while improving operational efficiency for commercial vehicles, delivery trucks, and equipment movement. Understanding the multifaceted benefits of properly designed driveway curb ramps can transform how logistics managers approach facility safety and productivity.

The logistics industry operates within increasingly complex regulatory environments where safety compliance directly impacts operational costs and liability exposure. Driveway curb ramps represent a proactive investment in infrastructure that addresses multiple safety challenges simultaneously. From reducing vehicle damage and driver fatigue to minimizing pedestrian hazards and equipment wear, these installations deliver measurable returns on investment through reduced maintenance costs and improved operational efficiency.

Critical Safety Challenges in Logistics Facility Access

Vehicle Damage Prevention and Cost Reduction

Commercial vehicles entering logistics facilities without proper transitional ramps frequently experience undercarriage damage, suspension stress, and tire wear acceleration. Sharp curb transitions create jarring impacts that accumulate over time, leading to premature component failure and unexpected maintenance costs. Fleet managers report significant reductions in repair expenses after installing quality driveway curb ramps at facility access points.

The financial impact extends beyond immediate repair costs to include vehicle downtime, replacement part procurement, and labor expenses. Large distribution centers processing hundreds of vehicle entries daily can experience substantial cumulative savings by addressing these transition points proactively. Insurance providers increasingly recognize facilities with proper access infrastructure as lower-risk operations, potentially offering reduced premium rates.

Driver Safety and Ergonomic Considerations

Professional drivers face occupational health risks from repetitive jarring motions when navigating poorly designed facility entrances. Sudden impacts at curb transitions contribute to back injuries, neck strain, and general fatigue that accumulates throughout long driving shifts. Implementing smooth driveway curb ramps reduces these ergonomic stressors significantly.

Driver satisfaction and retention rates improve when companies demonstrate commitment to operator comfort and safety. Professional drivers actively seek employment with companies that maintain high facility standards, making infrastructure investments valuable for human resource management. Reduced worker compensation claims and improved driver performance metrics justify the initial installation costs.

Operational Efficiency Improvements Through Proper Access Design

Traffic Flow Optimization

Smooth facility access points enable vehicles to maintain consistent speeds during entry and exit procedures, reducing bottlenecks that commonly develop at poorly designed transitions. Driveway curb ramps allow larger vehicles to navigate facility perimeters without significant speed reduction or complex maneuvering. This improvement becomes critical during peak operational periods when multiple vehicles require simultaneous access.

Loading dock efficiency correlates directly with access infrastructure quality, as delays at entry points cascade throughout the entire operation. Facilities with optimized access design report improved on-time delivery performance and enhanced customer satisfaction ratings. These operational improvements translate into competitive advantages within the logistics marketplace.

Equipment Longevity and Maintenance Reduction

Forklifts, pallet jacks, and other material handling equipment benefit significantly from smooth transitions between different surface levels. Abrupt elevation changes stress equipment components, leading to accelerated wear patterns and increased maintenance requirements. Quality driveway curb ramps extend equipment service life while reducing unexpected breakdowns that disrupt operations.

Maintenance teams report fewer hydraulic system failures, wheel replacement needs, and structural repairs when facilities incorporate proper transitional infrastructure. The predictable nature of equipment maintenance schedules improves after installation, allowing for better resource planning and inventory management of replacement parts.

Regulatory Compliance and Liability Management

ADA Accessibility Requirements

Commercial facilities must comply with Americans with Disabilities Act requirements for accessible pathways and vehicle access points. Properly designed driveway curb ramps ensure compliance with slope gradients, surface materials, and transition specifications mandated by federal accessibility standards. Non-compliance exposes facilities to significant legal liability and potential operational restrictions.

Regular accessibility audits by regulatory agencies focus heavily on transition points between different surface levels. Facilities with compliant infrastructure avoid costly retrofitting requirements and maintain uninterrupted operations. Legal counsel increasingly recommends proactive accessibility improvements as essential risk management strategies.

Insurance and Risk Mitigation

Insurance carriers evaluate facility infrastructure when assessing risk profiles for commercial properties. Well-maintained access points with appropriate safety features demonstrate management commitment to risk reduction. This proactive approach often results in reduced insurance premiums and improved coverage terms for logistics operations.

Liability exposure from vehicle accidents, pedestrian injuries, or equipment damage decreases substantially when facilities maintain proper transitional infrastructure. Legal precedents increasingly hold property owners responsible for foreseeable hazards that could have been mitigated through reasonable infrastructure investments.

Material Selection and Installation Considerations

Durability and Weather Resistance

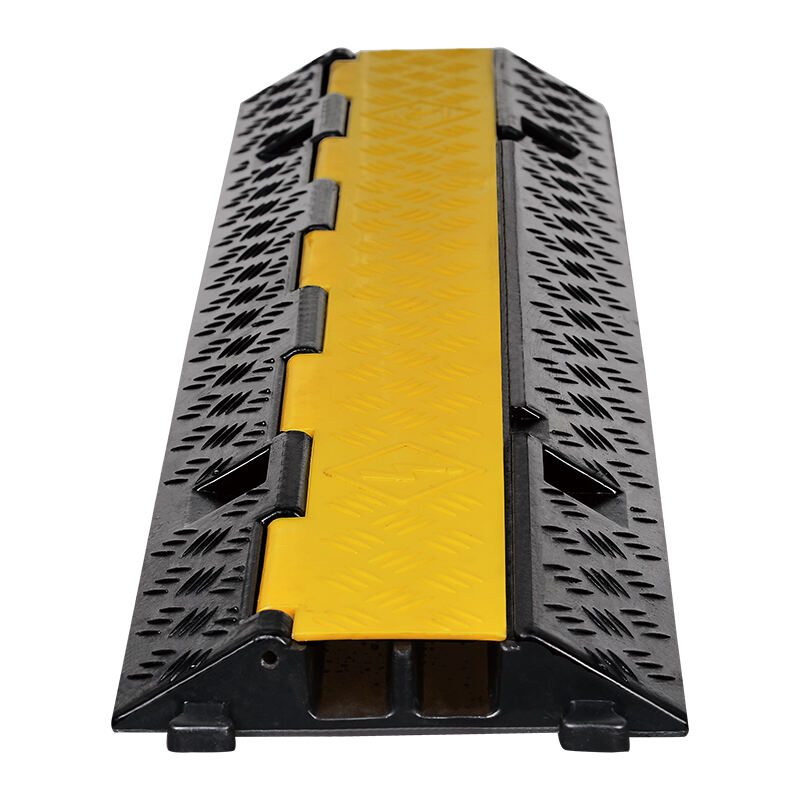

Commercial-grade driveway curb ramps must withstand heavy vehicle loads, extreme weather conditions, and continuous use without degradation. Rubber and polymer materials offer superior flexibility and longevity compared to concrete alternatives, while providing better traction in wet conditions. UV resistance prevents material breakdown from extended sun exposure common in outdoor applications.

Installation location affects material selection significantly, with covered areas allowing different options than fully exposed positions. Facilities in regions with freeze-thaw cycles require materials that maintain flexibility across temperature extremes. Proper material selection ensures long-term performance without frequent replacement costs.

Load Capacity and Structural Engineering

Heavy commercial vehicles require driveway curb ramps designed for substantial weight loads without deformation or failure. Engineering specifications must account for concentrated loads from truck axles, dynamic loading from vehicle movement, and repetitive stress cycles from continuous use. Proper structural design prevents premature failure and maintains smooth transitions over extended service life.

Installation methods significantly impact long-term performance, with proper anchoring and surface preparation essential for maintaining structural integrity. Professional installation ensures optimal load distribution and prevents shifting or settling that could create new hazards. Quality installation practices extend service life while maintaining safety performance.

Cost-Benefit Analysis for Logistics Operations

Initial Investment Versus Long-Term Savings

While driveway curb ramps require upfront capital investment, the cumulative savings from reduced vehicle maintenance, insurance costs, and operational delays typically recover initial costs within the first year of operation. Large facilities processing significant vehicle traffic experience faster payback periods due to higher utilization rates and greater potential savings.

Financial modeling should include both direct cost savings and indirect benefits such as improved customer satisfaction, driver retention, and reduced liability exposure. These intangible benefits often exceed direct savings but require comprehensive analysis to quantify properly.

Productivity and Efficiency Gains

Operational efficiency improvements from smooth facility access translate into measurable productivity gains throughout the logistics operation. Reduced entry and exit times allow for higher vehicle throughput during peak periods. Equipment availability increases due to reduced maintenance requirements, improving overall facility capacity utilization.

Customer service metrics improve when delivery operations experience fewer delays and equipment issues. These improvements enhance competitive positioning within the logistics marketplace while supporting long-term business growth objectives.

FAQ

What weight capacity should commercial driveway curb ramps support

Commercial driveway curb ramps should support loads of at least 40,000 pounds to accommodate fully loaded commercial vehicles. Heavy-duty applications may require ramps rated for 60,000 pounds or higher, depending on the specific vehicle types accessing the facility. Proper engineering analysis ensures adequate safety margins for dynamic loading conditions.

How do weather conditions affect ramp performance and maintenance

Weather exposure affects different ramp materials differently, with rubber and polymer options generally providing better performance in extreme conditions than concrete alternatives. Regular cleaning and inspection help maintain traction surfaces and identify potential wear issues before they become safety hazards. Facilities in harsh climates may require more frequent maintenance schedules.

What installation requirements ensure optimal long-term performance

Proper surface preparation, including cleaning and leveling, provides the foundation for successful installation. Mechanical anchoring systems distribute loads effectively while preventing shifting or settling over time. Professional installation following manufacturer specifications ensures warranty coverage and optimal performance throughout the service life.

How do facilities measure return on investment for access infrastructure improvements

ROI calculations should include reduced maintenance costs, lower insurance premiums, decreased liability exposure, and improved operational efficiency. Tracking vehicle damage incidents, equipment maintenance costs, and operational delays before and after installation provides quantifiable metrics. Most commercial facilities achieve positive ROI within 12-18 months of installation.